The combination of PICKLOGGER™ and MYSOIL CLASSIFICATION™ in fruit crops

By Marnus Ferreira, Head of Grains, Agri Technovation

This article focuses on three actions or concepts as outlined in the title: measure, understand and improve. Together these three actions represent the best current method available for improving yields meaningfully, especially on farms that already perform well. It gives the producer the ability to apply the basic practices as best as possible.

While crop prices are under increasing pressure due to socio-economic issues, the formidable combination of good yields and quality remains at the heart of sustainable farming operations and the 3-action method can certainly assist in achieving this.

Measure

Until recently, yield measurement of fruit crops was limited to block or orchard level and not nearly as accurate and informative as yield maps produced by grain harvesters. This changed, of course, with the commercialisation of the inventive PICKLOGGER™ device, the harvesting tool that won the prize for best innovation at the 2021 Biostimulants World Congress in Miami, VSA. This device makes it possible to produce yield maps up to tree level and is already commercially available for citrus, avocados, table grapes/vines, apples, pears and now also watermelon, melons and so on.

This precision technology creates, for the first time in history, the ability to accurately measure yields of certain permanent crops at a commercial level. Armed with generated yield maps, a producer can see exactly how yields vary within orchards.

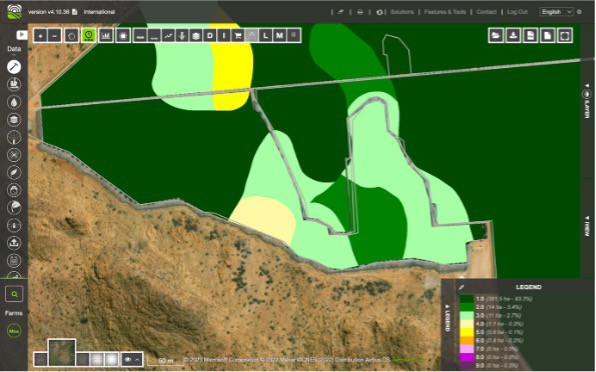

Figure 1 is an example of soft citrus yield data generated by PICKLOGGER™. It clearly indicates those areas in the block (predominately the eastern side), that are producing significantly lower yields.

Figure 1. Yield map of soft citrus generated by the PICKLOGGER™ device. Note the legend at the bottom right (unit is t/ha) – the variation from 0-18t/ha to 130-165t/ha is noticeable. The greatest variation is between the western (high) and eastern (low) areas.

The yield distribution ranges from 0 – 18t/ha to 130 – 165t/ha. Characteristic of this type of data (and based on multi-year data), is that certain areas in the block repeatedly produce high, and others repeatedly low yields. Thus, the average yield of the block may be 75t/ha, but the variation between the different areas is massive. About 49% of the block yields below 50t/ha and ±10% above 100t/ha.

Identifying and investigating these varying areas (by measuring) is the first significant step to raising the average of the block. An increase in production of 10t/ha in only the weaker areas (which should be easy to achieve once the problem has been identified), could result in an increase in the average production of the block of at least 5t/ha.

Understand

It is well known that up to ±70% of production can be determined by irrigation. Although irrigation is used to maintain sufficient moisture in the plant, it is mainly the soil and climate that determine how that moisture should be applied in terms of irrigation practices and strategy. The irrigation practice used for a deep loamy soil is not necessarily going to be successful in a very shallow sandy and rocky soil. In order to apply moisture in such a way that ensures uptake by the plant, the physical properties of the soil must first be thoroughly understood.

In this instance Agri Technovation’s MYSOIL CLASSIFICATION™ service provides the answer. It unlocks the characteristics of the soil, which in turn determine the best (most suitable) irrigation practice and strategy to be applied. A comparison of Figures 1 (yield map), 2 (soil type map) and 3 (wetness indication map) clearly illustrates how the soil type directly affects crop production, due to inter alia the chosen irrigation practice.

Note specifically the eastern areas of the block, where the lower yield area (indicated in Figure 1) correlates with the presence of 3 different soil types (pink, brown and dark green areas in Figure 2) which are shallower and therefore, could easily have been over-irrigated. Signs of wetness represent visible reducing conditions in the soil (oxygen-poor).

Figure 3 indicates those areas in the block where signs of wetness have been identified. Areas marked in dark green have no visible signs, while lighter green to yellow shades indicate areas where signs of wetness were noticed. This investigation indicates clearly that the deeper soil (lighter green area in Figure 2) was irrigated correctly, resulting in good production. However, the shallower soils in the eastern area of the block are already showing signs of wetness – in an area where rainfall is low – and are therefore receiving more water than the soil is able to store, leading to oxygen-poor conditions.

Figure 2. Soil type map of the same area depicted in Figure 1. There are 4 different soil types present in the actual block, 6 in total in the figure. Note the strong correlation between the lower producing areas to the east of Figure 1 and the presence of the pink, brown and dark green soils (all of which have limiting retaining layers in the subsoil).

Figure 3. Signs of wetness map. Dark green areas (symbol 1 in the legend) indicate that no signs of wetness were identified. Lighter green to yellow (symbol 2-5 in the legend) is indicative of increasing degrees of wetness and thus oxygen-poor conditions. Also note the correlation between those wetter areas and the decrease in production in Figure 1.

Without oxygen in the profile, roots cannot respire and the plant’s primary functions are thus inhibited. If the selected irrigation practice results in long periods of both water and/or oxygen-poor conditions in the soil (and this is strongly related to the soil’s physical properties), production will be adversely affected. Correct execution of just this one aspect (irrigation), represents approximately 70% of overall success in optimizing production. Certainly this would be worth one’s while?

Improve

Meaningful data collection always creates an opportunity for change. This, after all, is why we measure, to understand what a realistic yield expectation would be, in order to implement plans aimed at improving production.

Now that the problem illustrated in Figures 1, 2 and 3 has been clearly determined, solutions can be implemented. The ideal solution here would be to irrigate/manage the western deeper soil and eastern shallower soil separately. In certain instances this may require the separation of irrigation lines, but it could also be as simple as putting up lower-flow irrigation heads in the eastern area (provided they are micros), or blocking every second/third dripper, and so on.

Furthermore, scheduling can be adapted to a pulse strategy, where smaller amounts of water are applied more frequently. This always works well in combination with a mulch application, which stimulates shallower root development and thus drives the root mass closer to the surface, and out of the wet unfavorable subsoil.

These are relatively small steps to take, but they could lead to significant results. By measuring the production (using PICKLOGGER™) and understanding the problem (MYSOIL CLASSIFICATION™) the solution can be implemented and production improved.